Redesigning the Wheelchair

Goal

Redesign and reengineer the wheelchair to make it lighter, cheaper, more efficient, and to change the current social stigma behind the wheelchair.

About

Collaborating with Sophia Malthus and industrial designer Alberto Esses to create a personalized wheelchair for Sophia to increase her quality of life and mental health.

Creating A Design Package

With the measurements from the specification sheet, I created a design package using SolidWorks so that Alberto could create a design around it.

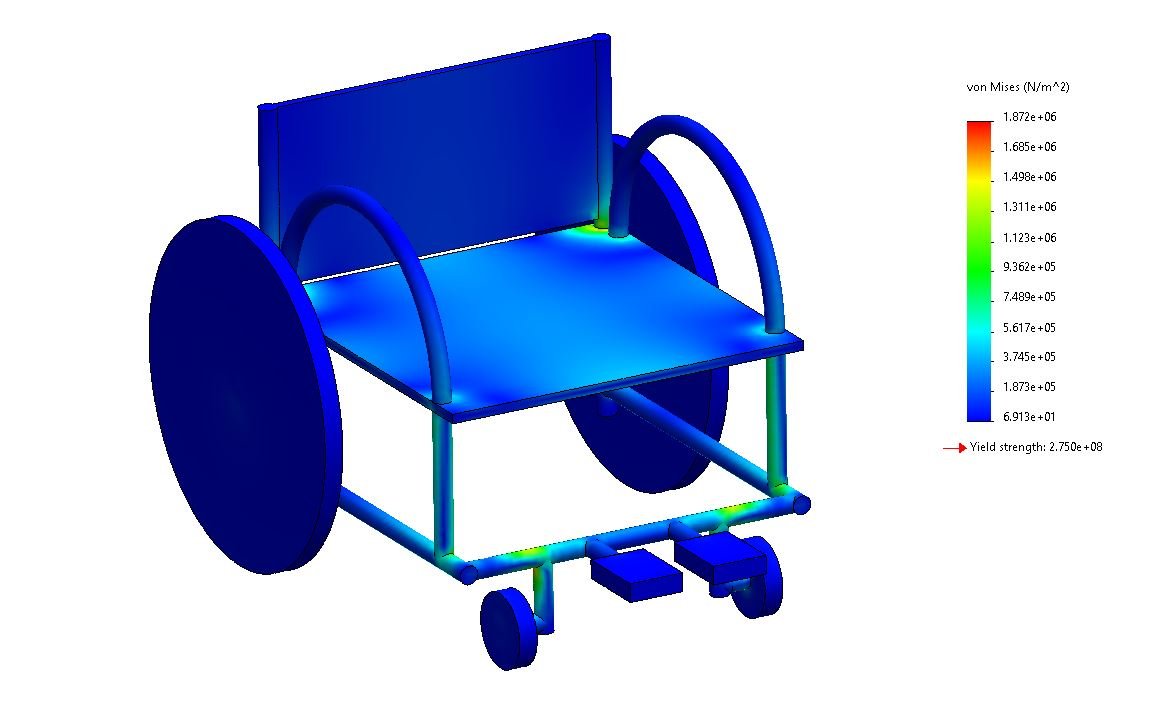

FEA Simulations

I created a simplified version of a wheelchair and ran it through a static FEA load simulations to better understands the forces at work. Using the design package, Alberto created a 3D shell model of his design. I converted the shell model into a solid body and ran it through a static FEA load simulations to figure out weak spots in the design and give feedback to Alberto.

Simplified Wheelchair Stress Analysis.

Based on this study, the area of concern that we needed to focus on was the connection between the frame and the wheels as well as the connection between the frame and the caster wheels.

Current design model with simplified wheels and caster wheels.

Similarly to the simplified wheelchair study, this study confirmed that an area of concern is the area of connection of the wheels as well as the caster wheels. I am currently in the process of researching possible ways to connect the sets of wheels to lower the stresses upon them. However, since the expected load (500N) is not very high, there isn’t a high risk of failure.

Ergonomics

One of the biggest issues Sophia faces is pressure sores. Pressure sores occur when veins and arteries are pinched for an extended period of time. Due to the nature of Sophia’s injury, she is not able to move to readjust her weight distribution. I have been researching possible ways to create a custom cushion for the wheelchair that shifts her weight distribution at set time intervals.

Similarly to a massage chair or cushion. My plan is to build a custom seat that has a similar arrangement of massage rollers that are activated at certain time intervals to help shift the weight distribution of Sophia and prevent pressure sores from occurring. I have currently ordered the parts needed and am planning to build a functional prototype by the end of this year.

Challenges and Next Steps

Manufacturing

I am currently researching different manufactures and methods to create a prototype. One promising method is using 3D printed KyronMax carbon fiber-filament for our project due to the organic form and design of our wheelchair. While the expected load is around 50-60kg, much less than the load ranges of KyronMax, it is also an extremely light material compared to aluminum or steel, and for people like Sophia the weight of the wheelchair is a key aspect of their mobility and independence as a low weight wheelchair would allow her to pull it in and out of her car on by herself.

However, the 3D printing capabilities of this manufacturer would not be able to print one full solid body and would require us to split up the wheelchair into different components. This would also be beneficial as having the wheelchair be split into parts would allow for easier transportation and storage. One method that I am currently researching more about is the use of clamp latches that would be hidden from the outside by a compartment.

Funding

One of the biggest challenges we are facing is funding this project. One of our biggest successes so far is getting a sponsorship by Alber, a wheelchair manufacturing company. They have provided two sets of their newest power assisted wheels with a total cost of nearly 30,000 dollars. One set has already been shipped to Sophia for use in her current wheelchair and another will be used in our wheelchair. We are also currently in a design competition by Wevolver and the Mitsubishi Corporation with a grand prize of 25,000 dollars in manufacturing costs. They are also one of the 3D printing manufacturers we have researched as potential candidates, this would be a huge step toward the creating of a fully functional, real scale prototype.

Final Concept and Renders

Design created by Alberto Esses and Alan Esses. Renders created by Alberto Esses.